Services

Tomography to Any Pipeline, Anytime!

Tomography for Any Pipeline, Anytime!

With our innovative tomography solutions, we provide real-time insights into behaviors within pipelines, making it easier to monitor and optimize pipeline performance. Our inTouch Electrode technology can be adapted to pipelines in various industries—including chemical, oil and gas, mining, pulp, and food sectors—without requiring costly custom spool pieces.

- Flexible Installation: Our InTouch electrode outlet adapter can be welded to existing pipelines, enabling easy addition of electrodes at multiple points. This scalable setup is tailored to meet your specific monitoring needs. In a typical installation 1-8 adapters are needed.

- Comprehensive Monitoring Solutions: Our EIT, ECT, optical, and ultrasound tomography technologies can be seamlessly retrofitted onto your pipeline, providing a cost-effective approach to gain valuable insights without significant modifications.

- On-Demand Measurements: Prepare as many monitoring locations as needed, and our team will handle the measurements. We deliver data reports directly to the cloud on a weekly basis, ensuring you stay informed on pipeline performance.

- No Upfront System Purchase Required: With our flexible service model, you pay only for what you need, gaining expert insights without the investment and maintenance costs of owning a system.

PREDIT's InTouch electrode!

Our InTouch electrode outlet (in grey) is designed to be welded directly onto your pipeline, streamlining installation and eliminating the need for an expensive spool piece.

Once installed, PREDIT provides a complete electrode structure with advanced EIT, ECT, and optical tomography capabilities. This setup enables precise, real-time monitoring, giving you valuable insights without costly modifications.

This approach is especially valuable for long trunk lines where chemical injections are used for separation processes. Our system allows for continuous monitoring and adjustment, providing critical insights into the distribution and effectiveness of chemical treatments without requiring extensive infrastructure changes.

Our service model ensures that you can implement tomography at multiple pipeline points, making it a perfect solution for complex, large-scale operations.

Pipeline Blockage and Flow Regime Monitoring by PREDIT

PREDIT offers state-of-the-art pipeline condition monitoring solutions designed to detect and prevent blockages before they become costly problems. Our advanced technology and dedicated service ensure that your pipelines remain in optimal condition, allowing you to focus on your core operations.

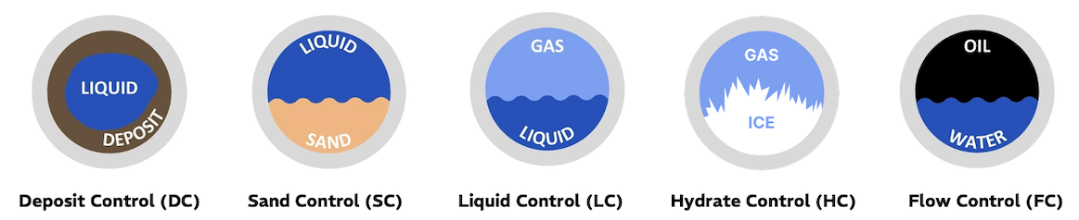

Deposit Control (DC): Deposit buildup around pipe walls in liquid-filled pipes. Keep pipelines open to ensure uninterrupted revenue. Avoid unexpected shutdowns. Optimize pipeline cleaning cycles.

Derbis Control (BC): Bottom sand/debris in liquid-filled pipes. Avoid unexpected shutdowns. Prevent pumps from being destroyed (accumulated sand starts to move sooner or later).

Hydrate Control (HC): Monitoring hydrates in a pipeline. Avoid hydrate problems in pipelines using ClampOn sensor technology.

Liquid Control (LC): Monitoring liquid in a pipeline. Detect watering interfaces during water push to optimize processes. Avoid safety hazards and chemical spills when opening a pipeline.

Flow Control (FC): Detection of stratified/turbulent flow regimes. Ensure chemicals are working correctly and expedite the separation process in oil terminals. Avoid hydrate blockages.

Deposit Problems

PREDIT has a novel technology to overcome deposition problems.

Key Phases of a Project:

- Contact: In this initial phase, we work closely with our clients to gain a comprehensive understanding of their requirements and objectives. The easiest way to schedule an appointment is through the top banner or contact us via WhatsApp at +358 40 147 8797 and +358 44 542 1199.

- Installation: PREDIT engineers install the necessary clamp-on or InTouch electrodes equipment on-site and will test its functionality. In limited cases, we may apply electrodes to monitor the flow, which can be installed on any pipeline even during operation. The technology is compatible with all pipeline materials, including metals, composites, and HDPE...

- Continuous monitoring: PREDIT visits the site at pre-agreed intervals.

- Reporting: All location tags are readable on a web service. The measurements will include reports on pipe shape and pipe thickness.

Project Timeframe:

Depending on the location, the monitoring tools can be installed within a timeframe ranging from 2 to 8 weeks.

Customized Technology Development for Process Diagnostics (S-Series)

At PREDIT, we take pride in our expertise in customizing technology solutions for process diagnostics tailored to our clients' specific needs. Our cost-effective modular platform enables us to build innovative applications that address the unique challenges faced by our customers. In addition to hardware, we deliver a tomographic program and cloud service to monitor all instruments and utilize data for customer support.

Key Phases of Custom Technology Development:

- Pre-Study: In this initial phase, we work closely with our clients to gain a comprehensive understanding of their requirements and objectives. Through meticulous analysis and collaboration, we lay the groundwork for a successful project.

- Design, Manufacture, and Piloting: Armed with the insights from the pre-study, we move forward with designing and manufacturing the customized technology. Our skilled team ensures the development of a robust and efficient solution. During the piloting phase, we rigorously test the technology to validate its performance and suitability for real-world applications.

- Refinement and Documentation: The piloting phase allows us to identify areas for improvement and refinement. We address any challenges and fine-tune the technology to optimize its functionality. Additionally, we provide comprehensive documentation that enables seamless integration and usage of the developed solution.

- Installing a cloud-based AI server: We utilize modern IoT technology to communicate with the devices. Leveraging AI data analytics, we update all devices periodically to optimize their performance and enhance customer service.

- Warranty and Support: After successful deployment, we offer a 10% warranty period to address any unexpected issues. Our dedicated support team is always available to assist clients during this phase and beyond.

Project Timeframe:

Understanding the unique nature of each project, we ensure flexibility in our project timeframe. The piloting phase typically spans three months, while the total project duration can range from 6 to 18 months, depending on the complexity and scope of the application.

Our Commitment to Innovation:

At PREDIT, we are driven by a passion for innovation and excellence. By combining our modular platform with the expertise of our skilled team, we deliver bespoke technology solutions that empower our clients to overcome challenges, optimize processes, and achieve enhanced efficiency and safety in their operations. Let us be your partner in custom technology development, and together, we will shape the future of process diagnostics.

Book an appointment, and let us show how PREDIT can enhance your operations.

We look forward to helping you achieve a safer and more efficient future.